Your Recent Search:

4 Questions to Streamline the Snow Plow Blade Bid Process

April 10, 2018

Purchasing a blade system rather than piece-meal parts saves time and money. You can cut the snow plow blade purchasing process down to once a year versus 4-5 times a year by starting with high quality blades.

Initially, the upfront costs are more, it is more cost effective to operate with a systems-based approach. High-quality materials, and product guarantees mean you replace blades less often, spend less time preparing for bids, and less downtime inherent with blade changes in the field.

Replacing low-bid blades is a common issue that occurs several times over the busy snow season. Not only is it difficult (and sometimes dangerous) to replace low-bid blades due to their weight and lack of customizable size, it takes about 45 minutes depending on the type and size of the plow to get the job done.

This means that your multi-vehicle fleet will have vehicles off the road, sometimes simultaneously, simply because poor equipment has caused downtime. This is totally avoidable!

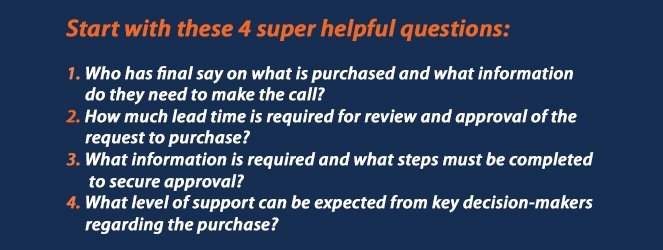

How can you streamline the bid process? Here’s a list to help you out!

Once you have answered these questions, consider purchasing a high-quality blade system rather than opting for low-bid blades. This way, you can save time, effort and money season after season like the Village of Buffalo Grove, IL did after switching from steel to carbide blades.

At the end of the day, the bid process is tedious no matter how much you’re able to streamline it. Avoid the process altogether by considering a switch in your low-bid blades.

Subscribe to our blog

Get notified when we post a new article

"*" indicates required fields