Your Recent Search:

Carbide-Tipped Road Grading Systems Outperform Standard Blades

June 1, 2018

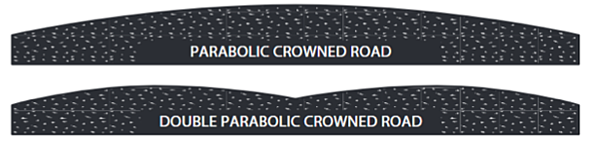

Gravel roads have 3 main elements.

- A crowned driving surface

- A shoulder area that slopes directly away from the edge of the driving surface

- A ditch

The basic shape of the cross section must be correct, or a gravel road will not perform well, even under very low traffic.

The road grader is the primary piece of equipment utilized in maintaining gravel roads. When using a grader switching to rotating, self-sharpening, replaceable tools can guarantee the right road grade every time.

Without carbide-tipped tools, roads can become misshapen. Using a worn standard blade gets poor results.

When choosing tools, a focus on superior design is critical. Carbide-tipped tools increase equipment productivity, provide a better-finished surface, and lower grading costs. They work especially well on these six common surface applications.

1. Gravel Reclamation and Maintenance

A scarifier quickly brings embedded rock to the surface so less new stone is needed.

2. Oil Road Reclamation

A scarifier requires less oil due to the mixing action of the rotating tools and better distribution on the entire road.

3. Ice and Snow Removal

A scarifier creates a grooved surface which facilitates better traction and the faster penetration of ice-melting chemicals; need fewer chemicals.

4. Asphalt Planning

A scarifier removes asphalt to the desired profile; bump grinds wheel ruts, washboards, asphalt pushes and frost heaves; removed material can be reused as fill.

5. Mixing in Calcium Chloride, Magnesium Chloride or other Dust Suppressants

A scarifier evenly mixes and distributes dust control agents; reduces the amount needed.

6. Chip and Seal Road Reclamation

- Tar sand road reclamation

- Pothole and washboard removal on dirt and gravel roads

- Spreading loose material

Subscribe to our blog

Get notified when we post a new article

"*" indicates required fields