- Halloween Sale! 15% off site wide 10/17 - 11/2 Shop Today!

Your Recent Search:

A scarifier is used for tearing up pavement, or when a gravel road surface is too hard for a standard motor grader blade to cut through. It can also be used to break up packed ice and asphalt.

Scarifying can be done by attaching extremely strong “teeth” to the grader that dig into hard surfaces without damaging the grader blade. It has 11 removable teeth that can be adjusted to cut a maximum depth of 12 inches. There are options to use both scarifier teeth and tools depending on the job.

Scarifier teeth attach to a shank and that attaches to heavy duty tubing on the grader. With the top of the scarifier pitched to the rear, the teeth lift and tear the material being loosened.

When operating in hard material, you might need to remove some of the teeth from the scarifier. However, do not remove more than five teeth because the force against the remaining teeth could shear them.

When removing teeth, take the center one out first and then alternately remove the other four teeth. This balances the scarifier and distributes the load evenly.

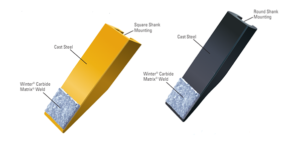

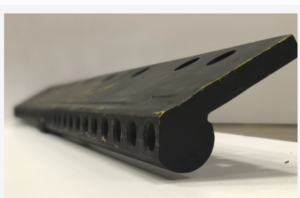

Scarifier tools attach to a scarifier board that replaces the moldboard on the motor grader. On the top, the scarifier board has prepunched holes that make it easy to attach to the motor grader.

On the bottom there are holes for the carbide-tipped tools to sit.

There are high speed steel tools and carbide- tipped tools.

While high-speed steel tools are less expensive, you’ll find splurging on carbide-tipped tools is a much better investment. They offer exceptional wear resistance and can last far longer before sharpening is required.

Additionally, they reduce downtime due to tool changes and minimize cratering. These blades have individual replaceable, rotating, self-sharpening tools that wear evenly.

"*" indicates required fields