Your Recent Search:

Cutting Edge Comparison – Mike Smith

Mike Smith out of Massachusetts decided to run a comparison using Winter Equipment’s Joma system against a similar cutting edge. The Joma system is installed on the front plow, while the competitors blade is on the wing. Check out the difference. The Joma blade clears through packed snow and ice, while the wing blade with the competitors edge is leaving a path of snow behind.

Related Products

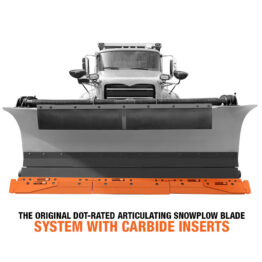

Joma 6000 Articulating Cutting Edge System by Winter®

Rated 4.47 out of 5 based on 17 customer ratings

Related FAQs

The recommended speed will vary based on the condition of the roads. Concrete / asphalt highway roads can support up to 45 mph, while asphalt city streets should be plowed around 10-15 mph. Chip seal and gravel roads can vary, but typically the slower the plow goes, the less road damage.

There are a multitude of variables that go into this decision. We typically recommend you give as much information as possible when either calling in or emailing an inquiry.

Steel is typically a good choice for low speed plowing on poor road conditions (potholes, manhole covers, bridge joints, etc). Steel blades can struggle to match the performance of carbide insert blades but may be the best choice in certain cases where blades are lost or damaged frequently due to impact as opposed to general use.

Carbide insert blades are the cream of the crop when talking snow plow cutting edge blades. They have the cutting power of steel with a vastly increased life expectancy. Carbide insert blades are fantastic for medium-high speed plowing on road surfaces with few obstructions. These conditions are ideal because the medium-high speed reduces impact on the blade, preventing brittle carbide to crack and wash out.

Rubber has a squeegee effect on the road and is the most lightweight material for snow plow blades. Rubber clears light snow, or heavy snow that has had time to melt from salt or brine. The nature of rubber which allows some flexibility when encountering obstacles in the road makes it a good choice for poor road conditions. Rubber is the best solution for any entity that finds itself plowing older decorative roads like brick or cobble stone because it can clear snow without ripping up the road substrate.

These are blade properties that affect the performance of the blade. They are both equally effective given the application.

An aggressive blade has more of a cutting effect. These blades are designed to limit the amount of surface area coming into direct contact with the road. They are best for ice and snowpack when the goal is to clear as much snow and ice with the blade as opposed to melting snow with salt or brine.

A road friendly blade is designed to increase the footprint the blade makes on the road. The increased surface area on the road helps to extend the wear life of the blade. It also allows the blade to “glide” instead of “cut” which helps to reduce road damage, and to avoid obstructions like manhole covers and bridge joints.

A system is a collection of products packaged together and shipped to your door. It is designed to keep everything for a blade install together and reduce the headache of ordering multiple pieces for blade changes. Each system includes smaller sections of blades for easier installation, 1 or 2 PlowGuards, hardware kits (with bolts, stover lock nuts, and conical washers), and includes freight costs. All of this can be ordered with one part number and comes in one box with installation instructions.

Easy Order – Easy Inventory – Easy Install