Your Recent Search:

Snow Plow Blade Types Explained

December 19, 2017

Whether you need to remove snow and ice from your driveway or clear miles of highway lanes, it’s the snow plow blade that really gets the job done. Let’s explore several types of snow plow blades and the features, benefits and challenges associated with each.

Steel

Pro: Aggressive blade with low initial cost

Con: Causes road damage and wears quickly

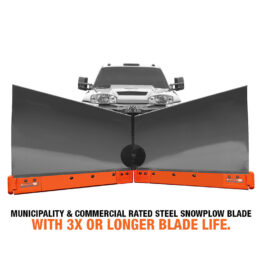

If you’re up against hard snowpack or ice, steel is a cost-friendly option. Its accessibility and low up front cost makes it the first choice of many municipalities. About 60-75% of the snow plows currently in circulation use steel blades.

Steel is especially helpful when it comes to cutting through packed snow and ice to the road surface, and decreasing salt or chemical usage. Due to its aggressiveness, a steel blade installed without guards or shoes results in premature wear and numerus blade changes throughout the season.

The downside is that using a steel blade alone can cause major damage to the road surface. Choosing a low budget steel blade for winter snow removal can lead to costly road repairs in the spring.

Rubber

Pro: Acts as a squeegee and protects the road surface

Con: wears quickly and is prone to tearing

Rubber snow plow blades have many advantages. Their flexibility makes them the perfect candidate for a blade that safely removes snow from decorative pavement. Rubber blades are most effective in slushy or light, fluffy snow. They can come pre-punched or slotted so you can custom-fit to the application you desire. They require a stabilization bar (the existing steel blade). You may also need longer cutting edge bolts to accommodate the added thickness that comes with using these blades.

Within the selection of rubber blades available, there exists a hierarchy. It’s important to ensure that your blades have a durometer level of at least 60 and a PSI (pounds per square inch) of at least 2000. Car tires typically have a durometer of 70. If your rubber blades don’t meet those requirements, premature wear, breakage and roll-under is inevitable.

Carbide

Pro: longest lasting blade

Con: higher upfront cost

Carbide blades are more expensive, but they are far superior to steel cutting edges. Product testing has shown that even one carbide blade has the strength of about 20-30 steel blades. Carbide is a hard material meaning it will most likely break before it wears down. This is why most carbide blade users protect their investment with a steel cover blade and plow guards.

Carbide blades maintain a sharp cutting edge, making them highly effective for ice removal. Because carbide is often used for machining through hard materials like stainless or carbon steel, they are perfect for situations where other materials would wear away. Ice is no match for these high-performing blades. Though many would consider carbide to be far too costly for small municipalities, these cutting edges will pay for themselves over time, as they rarely need to be replaced.

Subscribe to our blog

Get notified when we post a new article

"*" indicates required fields