Your Recent Search:

Top 5 Reasons to Switch to a Grading System

June 5, 2018

More than 50% of roads in America have a gravel surface, making them a critical part of our transportation system. A grading system can improve road surface, is easier on equipment, safer with less downtime in the field, more versatile and is more cost-effective.

Here are the top five reasons you should switch to a grading system.

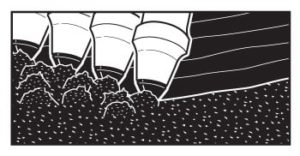

1. Improves Road Surfaces

With a grading system, you can penetrate hard-packed gravel roads easier. This allows you to quickly bring embedded rock to the surface. Grading systems consist of an adapter board and milling tools that fit on all standard grader and underbody blades.

2. Easier on Equipment

The less force equipment uses when operating, the longer it lasts. Grader operators can make fewer passes and use less horsepower and down pressure to do the job properly.

3. Safer & Less Downtime in the Field

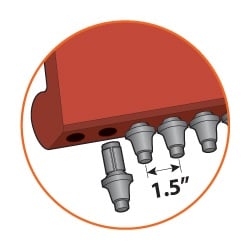

When you use a grader system, you only replace the worn milling tools, not the entire blade and fastening hardware. These can be replaced by one person and don’t require heavy lifting or taking the equipment back to the shop. You also don’t need any special installation tools, making changes in the field a breeze.

4. Versatility

Scarifiers are extremely hard. These carbide-tip tools rotate as they cut, thus sharpening themselves as they provide a uniform wear pattern.

5. Cost-effective

Grader operators can save money by purchasing less stone, and scarifiers last 5 times longer than standard blades. Also, a longer life means reduced replacement parts costs for road maintenance.

Subscribe to our blog

Get notified when we post a new article

"*" indicates required fields