Your Recent Search:

Getting the Most out of Your Rubber Cutting Edge

March 27, 2018

When you purchase a rubber cutting edge, the blade isn’t the only thing you need to worry about. There is an ecosystem of equipment and accessories that allow the cutting edge to function with the highest efficacy.

Here are a couple of the accompaniments that truly facilitate optimum snow and ice removal when paired with a rubber cutting edge.

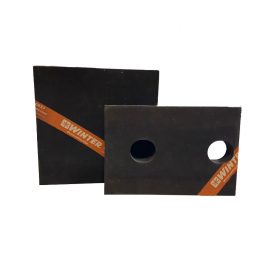

- Backer Blade. This eliminates rolling beneath the moldboard and increases productivity. The backer blade also allows the driver to finish the job even if the rubber has worn back without damaging the mold board.

- Plow Guards. These protect plow ends from curb damage. They can typically be designed to fit front or side-mount plow blades, loader or scraper blades, or even underbody blades.

Finally, to get the most out of your rubber cutting edge, it’s crucial that it’s set in the correct position. Often times, municipalities unknowingly make the mistake of setting the cutting edge too low to the ground. Perhaps it’s due to the belief that the cutting edge should be flush with the surface of the pavement.

However, this can result in damage to the rubber cutting edge and poor snow/ice removal. It’s recommended that the back edge of the rubber blade should extend no more than the width of the rubber (i.e. the maximum overhang for a 1 ½ ” blade is 1 ½”.)

Rubber edges can also be reversed or flipped to the opposite side. This adjustment can be made prior to each season or snow event as necessary. It only takes about 20-30 minutes and can prove to be a cost-savings measure.

In fact, Winter® Equipment’s WinterFlex® system comes pre-punched with a backer blade pre-furnished with bushings that allow you to flip the blade once the first side wears down. WinterFlex® rubber blades also have two sheets of polyurethane that provide durability and extended wear life. This saves time, increases safety, and ensures optimal performance value.

For more information on WinterFlex® blades, click here. To become a cutting edge expert, click below to download the latest free offer from Winter® Equipment.

Subscribe to our blog

Get notified when we post a new article

"*" indicates required fields