Description

100% Satisfaction Guaranteed.

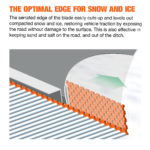

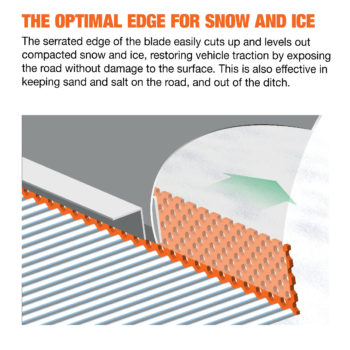

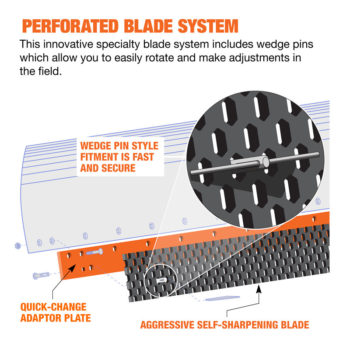

Superior Cutting –The self-sharpening technique allows for superior cutting eliminating ice, snowpack, potholes, and washboards.

Safe Installation –Sectional blades replace dangerous full-length cutting edges and the ability to rotate the blades helps manage uneven wear.

Unique features – Mounting board is a universal fit for the perforated edge or scarifier boards.

Fuel Consumption –Always sharp edge will decrease your down pressure which allows you to save on fuel cost.

Best Used For

- Roads: Gravel and dirt roads

- Speed: Low

- Plow Type: Underbody and front reversible plows

- Angle of Attack: 55° – 70°

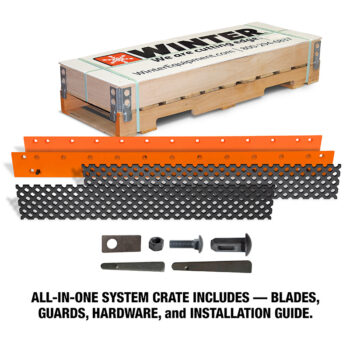

System Includes

- Two Sections of Adapter Boards

- Three Perforated Edges

- One Bag of Specialty Hardware

- Grade 8 Hardware

100% Satisfaction Guaranteed.

Superior Cutting –The self-sharpening technique allows for superior cutting eliminating ice, snowpack, potholes, and washboards.

Safe Installation –Sectional blades replace dangerous full-length cutting edges and the ability to rotate the blades helps manage uneven wear.

Unique features – Mounting board is a universal fit for the perforated edge or scarifier boards.

Fuel Consumption –Always sharp edge will decrease your down pressure which allows you to save on fuel cost.

Best Used For

- Roads: Gravel and dirt roads

- Speed: Low

- Plow Type: Underbody and front reversible plows

- Angle of Attack: 55° – 70°

System Includes

- Two Sections of Adapter Boards

- Three Perforated Edges

- One Bag of Specialty Hardware

- Grade 8 Hardware

Reviews

There are no reviews yet.