Description

Clear Snow Without Destroying the Surfaces You’re Hired to Protect

If you’re running a skid steer on commercial properties, you already know the problem: steel edges clear well but tear up every surface they touch—and rubber edges protect the surface but wear through fast and leave snow behind. Winter Equipment’s 7′ Polyurethane Skid Steer Cutting Edge eliminates that tradeoff. You get a commercial-grade plow blade that scrapes clean on the first pass and doesn’t leave a mark on the surface underneath.

Take Control of Your Snow Removal Operation

- Stop Damaging Client Property – This commercial-grade polyurethane edge clears snow from concrete, pavers, sealed asphalt, and coated garage floors without the scratching and gouging that steel edges leave behind—and without the liability that comes with it

- Outlast Rubber 3–5× – Our polyurethane formulation dramatically outlasts standard rubber edges in comparable conditions, which means fewer mid-season blade changes, less downtime, and more billable hours on the lot instead of in the shop

- Flip It and Double the Life – The reversible design lets you flip the edge when one side wears, effectively doubling your service life before replacement—a significant cost advantage when you’re running equipment hard on commercial routes

- Run Quiet in Garages and Neighborhoods – Dramatically quieter than steel edges, so you can clear enclosed parking structures without the deafening echo and plow residential neighborhoods at 4 AM without generating noise complaints

- Protect Your Skid Steer and Plow Frame – Polyurethane absorbs the impacts from curb strikes, expansion joints, bollards, parking stops, and garage thresholds that would send a jolt straight through a steel edge—reducing stress on your skid steer’s frame, hydraulics, and attachment plate

Built for Skid Steers and Commercial Plow Operations

When your skid steer hits a parking stop at operating speed, the force has to go somewhere. With a steel edge, it goes straight into your frame, your attachment plate, and your hydraulic system. With polyurethane, the edge flexes and absorbs the impact—protecting your equipment and the obstacle.

Our 7′ polyurethane cutting edge is engineered for the kind of work skid steers do—clearing garages, lots, and commercial properties where surface damage means lost contracts and noise means complaints. Rated to perform in temperatures down to –50°F, our polyurethane maintains the rigidity needed for a clean first-pass scrape while being gentle on every surface you cross—a combination that standard rubber and steel edges simply can’t deliver.

This is also the right edge for contractors running 7′ residential truck plows on premium driveways and HOA properties where steel isn’t an option and rubber wears out too fast.

Ideal Applications:

- Parking Garages – Polyurethane is the ideal cutting edge for enclosed structures where steel noise is amplified to deafening levels and coated concrete floors are expensive to repair. The edge flexes over expansion joints and garage thresholds without catching, chipping, or gouging

- Commercial Lots and Retail Centers – Clear storefronts, pedestrian areas, and decorative concrete around shopping centers and office parks without risking damage to surfaces that cost your clients thousands to install

- Residential Service Routes – Serve premium driveways, sealed asphalt, and HOA communities where surface protection is a contract requirement—not just a nice-to-have

- Hospitals, Campuses, and Facilities – Operate during noise-restricted hours and clear mixed-surface properties where surface damage creates both liability concerns and maintenance costs

Equipment Compatibility:

This 84″ cutting edge fits any 7′ skid steer blade or 7′ residential truck plow. It’s supplied as an undrilled blank—use your existing edge as a drilling template to match your specific bolt pattern and mounting configuration. If you’re unsure whether a 7′ edge is the right size for your setup, measure your existing edge or contact us before ordering.

Getting Started Is Simple:

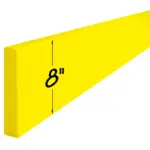

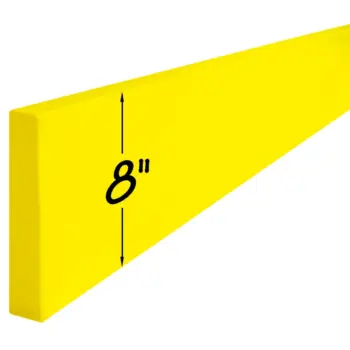

- ADD TO YOUR CART Add the 84″ x 8″ x 1.5″ polyurethane cutting edge for your 7′ skid steer or residential plow to your cart

- EASY CHECKOUT Our simple purchasing process makes ordering straightforward, even if it’s your first time buying from us—and we know how to work with government and commercial purchasing requirements

- FOCUS ON WHAT MATTERS Get back to clearing lots and serving clients with an edge that protects their property instead of tearing it up

Product Specifications:

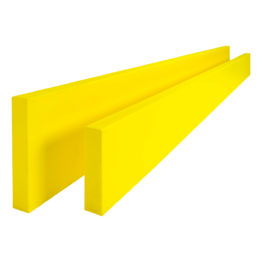

- Dimensions: 84″ x 8″ x 1.5″

- Price: $508.00 — Part # 5004-450-422

- Material: High-performance polyurethane (urethane) with superior wear and abrasion resistance, engineered to perform in temperatures down to –50°F

- Design: Supplied as an undrilled blank for custom fitting to your specific equipment

- Reversible: Flip the plow blade when one side wears to extend service life

- Instructions: Comprehensive mounting guide included with every purchase

Rubber Wears Out. Steel Tears Things Up. There’s a Better Option.

Every commercial snow removal operator faces the same dilemma. Standard rubber edges protect surfaces, but they wear through in weeks under heavy commercial use—leaving you changing blades mid-season while jobs pile up. Steel edges last longer, but they gouge sealed concrete, scratch decorative pavers, and leave rust marks on every surface they touch. On properties where surface protection is written into the contract, steel isn’t even an option.

Winter Equipment understands that frustration. You shouldn’t have to choose between an edge that lasts and an edge that doesn’t destroy your client’s property. That’s exactly why we developed our polyurethane cutting edges—to eliminate that compromise entirely.

Our polyurethane formulation delivers the clearing performance of a rigid edge with the surface protection your clients demand. It outlasts standard rubber 3–5× in comparable conditions, operates quietly enough for enclosed garages and residential neighborhoods, and absorbs impacts that would damage both the surface and your equipment. It’s a straightforward upgrade that changes the economics of your operation: fewer blade changes, fewer damage claims, and more contracts you can confidently say yes to.

Protect client property and your reputation—every pass, every lot, every season.

Winter Equipment: Trusted by snow removal professionals since 1989.

Purchase Today Request a Quote

Practical Answers to Common Questions

How do I know if this is the right size for my equipment?

This 84″ edge fits any 7′ skid steer blade or 7′ residential truck plow. The simplest way to confirm is to measure your existing edge—if it’s 84″ long, this is the right size. The edge is supplied as an undrilled blank, so it adapts to any bolt pattern and mounting configuration. Just use your existing edge as a drilling template. If you’re unsure about sizing, contact us before ordering.

How does polyurethane compare to the rubber edge I’m running now?

If you’re already running rubber because you can’t use steel on your contracts, polyurethane is a direct upgrade in every category that matters. It clears better—polyurethane stays rigid enough to scrape clean on the first pass instead of folding and dragging like rubber does in cold temperatures. It lasts dramatically longer—our customers typically report 3–5× the service life of standard rubber in comparable conditions, which means fewer mid-season blade changes and less downtime. And it still provides the surface protection your contracts require. The reversible design doubles the usable life even further.

Will polyurethane clear snow as effectively as steel?

Our polyurethane formulation maintains the rigidity needed for effective first-pass clearing on commercial surfaces—parking garages, concrete lots, asphalt, and sealed surfaces all get a clean scrape. It clears significantly better than rubber because it holds its shape in cold temperatures rather than deflecting under load. You lose the ability to scrape ice off a surface the way steel does, but for snow clearing on properties where steel isn’t allowed, polyurethane delivers the closest performance match without the surface damage.

How does polyurethane hold up over time in heavy commercial use?

In the high-wear environment of commercial snow removal—repeated passes, heavy down-pressure, abrasive surfaces—how an edge wears matters as much as how long it lasts. Polyurethane wears evenly and smoothly, maintaining consistent clearing performance and surface protection throughout the season. Our customers in commercial applications typically report 3–5× the service life of standard rubber edges. Install it, flip it when one side wears down, and trust that it’s performing just as well on your last lot of the night as it did on your first.

Can I use this in a parking garage?

This is one of the best applications for polyurethane. Parking garages present a unique combination of challenges that polyurethane handles better than any other edge material: the coated concrete floors are expensive to repair and easily scratched by steel, the enclosed structure amplifies steel-on-concrete noise to the point of being physically uncomfortable, and the constant expansion joints and garage thresholds catch rigid steel edges and jolt the equipment. Polyurethane clears the coated surface without scratching, operates at a fraction of the noise level of steel, and flexes over joints and transitions instead of catching on them.

What’s the difference between polyurethane and UHMW or HDPE plastic edges?

You may see cheaper “poly” edges sold online made from UHMW or HDPE plastic. While those materials offer some surface protection, they lack the rigidity and abrasion resistance of true polyurethane—a critical difference in commercial use where you’re putting serious down-pressure on the edge and running it across abrasive concrete for hours at a time. Our urethane formulation is specifically engineered for snow plowing—it stays firm enough to scrape effectively in temperatures down to –50°F while absorbing impacts that would chip or crack harder plastics. Polyurethane also has superior rebound memory, meaning it returns to its original shape after flexing over expansion joints and surface obstacles rather than permanently deforming under repeated stress the way UHMW can. For commercial operations where the edge has to perform under real load, the difference matters.

How difficult is installation?

Installation is straightforward. The edge is supplied as an undrilled blank—use your existing edge as a drilling template with standard power tools. At 84″ and 1.5″ thick, you’ll want the edge supported on a flat surface during drilling. The polyurethane material drills cleanly with standard bits at moderate speed. We include detailed mounting instructions with every purchase, and our knowledgeable staff is available if you have questions about your specific equipment.

Is the edge really that much quieter than steel?

The difference is dramatic—and in enclosed spaces like parking garages, it’s the difference between a functional working environment and an unbearable one. Steel-on-concrete in a parking structure echoes and amplifies to the point that it can cause hearing damage during extended shifts. Polyurethane operates at a fraction of that noise level. On open commercial lots and residential neighborhoods, the reduced noise means you can start earlier, run later, and serve noise-sensitive clients like hospitals and residential communities without generating complaints.

What if it doesn’t work for my setup?

Our products are backed by a Satisfaction Guarantee. If something isn’t right, we’ll work with you to make it right.

Clear Snow Without Destroying the Surfaces You’re Hired to Protect

If you’re running a skid steer on commercial properties, you already know the problem: steel edges clear well but tear up every surface they touch—and rubber edges protect the surface but wear through fast and leave snow behind. Winter Equipment’s 7′ Polyurethane Skid Steer Cutting Edge eliminates that tradeoff. You get a commercial-grade plow blade that scrapes clean on the first pass and doesn’t leave a mark on the surface underneath.

Take Control of Your Snow Removal Operation

- Stop Damaging Client Property – This commercial-grade polyurethane edge clears snow from concrete, pavers, sealed asphalt, and coated garage floors without the scratching and gouging that steel edges leave behind—and without the liability that comes with it

- Outlast Rubber 3–5× – Our polyurethane formulation dramatically outlasts standard rubber edges in comparable conditions, which means fewer mid-season blade changes, less downtime, and more billable hours on the lot instead of in the shop

- Flip It and Double the Life – The reversible design lets you flip the edge when one side wears, effectively doubling your service life before replacement—a significant cost advantage when you’re running equipment hard on commercial routes

- Run Quiet in Garages and Neighborhoods – Dramatically quieter than steel edges, so you can clear enclosed parking structures without the deafening echo and plow residential neighborhoods at 4 AM without generating noise complaints

- Protect Your Skid Steer and Plow Frame – Polyurethane absorbs the impacts from curb strikes, expansion joints, bollards, parking stops, and garage thresholds that would send a jolt straight through a steel edge—reducing stress on your skid steer’s frame, hydraulics, and attachment plate

Built for Skid Steers and Commercial Plow Operations

When your skid steer hits a parking stop at operating speed, the force has to go somewhere. With a steel edge, it goes straight into your frame, your attachment plate, and your hydraulic system. With polyurethane, the edge flexes and absorbs the impact—protecting your equipment and the obstacle.

Our 7′ polyurethane cutting edge is engineered for the kind of work skid steers do—clearing garages, lots, and commercial properties where surface damage means lost contracts and noise means complaints. Rated to perform in temperatures down to –50°F, our polyurethane maintains the rigidity needed for a clean first-pass scrape while being gentle on every surface you cross—a combination that standard rubber and steel edges simply can’t deliver.

This is also the right edge for contractors running 7′ residential truck plows on premium driveways and HOA properties where steel isn’t an option and rubber wears out too fast.

Ideal Applications:

- Parking Garages – Polyurethane is the ideal cutting edge for enclosed structures where steel noise is amplified to deafening levels and coated concrete floors are expensive to repair. The edge flexes over expansion joints and garage thresholds without catching, chipping, or gouging

- Commercial Lots and Retail Centers – Clear storefronts, pedestrian areas, and decorative concrete around shopping centers and office parks without risking damage to surfaces that cost your clients thousands to install

- Residential Service Routes – Serve premium driveways, sealed asphalt, and HOA communities where surface protection is a contract requirement—not just a nice-to-have

- Hospitals, Campuses, and Facilities – Operate during noise-restricted hours and clear mixed-surface properties where surface damage creates both liability concerns and maintenance costs

Equipment Compatibility:

This 84″ cutting edge fits any 7′ skid steer blade or 7′ residential truck plow. It’s supplied as an undrilled blank—use your existing edge as a drilling template to match your specific bolt pattern and mounting configuration. If you’re unsure whether a 7′ edge is the right size for your setup, measure your existing edge or contact us before ordering.

Getting Started Is Simple:

- ADD TO YOUR CART Add the 84″ x 8″ x 1.5″ polyurethane cutting edge for your 7′ skid steer or residential plow to your cart

- EASY CHECKOUT Our simple purchasing process makes ordering straightforward, even if it’s your first time buying from us—and we know how to work with government and commercial purchasing requirements

- FOCUS ON WHAT MATTERS Get back to clearing lots and serving clients with an edge that protects their property instead of tearing it up

Product Specifications:

- Dimensions: 84″ x 8″ x 1.5″

- Price: $508.00 — Part # 5004-450-422

- Material: High-performance polyurethane (urethane) with superior wear and abrasion resistance, engineered to perform in temperatures down to –50°F

- Design: Supplied as an undrilled blank for custom fitting to your specific equipment

- Reversible: Flip the plow blade when one side wears to extend service life

- Instructions: Comprehensive mounting guide included with every purchase

Rubber Wears Out. Steel Tears Things Up. There’s a Better Option.

Every commercial snow removal operator faces the same dilemma. Standard rubber edges protect surfaces, but they wear through in weeks under heavy commercial use—leaving you changing blades mid-season while jobs pile up. Steel edges last longer, but they gouge sealed concrete, scratch decorative pavers, and leave rust marks on every surface they touch. On properties where surface protection is written into the contract, steel isn’t even an option.

Winter Equipment understands that frustration. You shouldn’t have to choose between an edge that lasts and an edge that doesn’t destroy your client’s property. That’s exactly why we developed our polyurethane cutting edges—to eliminate that compromise entirely.

Our polyurethane formulation delivers the clearing performance of a rigid edge with the surface protection your clients demand. It outlasts standard rubber 3–5× in comparable conditions, operates quietly enough for enclosed garages and residential neighborhoods, and absorbs impacts that would damage both the surface and your equipment. It’s a straightforward upgrade that changes the economics of your operation: fewer blade changes, fewer damage claims, and more contracts you can confidently say yes to.

Protect client property and your reputation—every pass, every lot, every season.

Winter Equipment: Trusted by snow removal professionals since 1989.

Purchase Today Request a Quote

Practical Answers to Common Questions

How do I know if this is the right size for my equipment?

This 84″ edge fits any 7′ skid steer blade or 7′ residential truck plow. The simplest way to confirm is to measure your existing edge—if it’s 84″ long, this is the right size. The edge is supplied as an undrilled blank, so it adapts to any bolt pattern and mounting configuration. Just use your existing edge as a drilling template. If you’re unsure about sizing, contact us before ordering.

How does polyurethane compare to the rubber edge I’m running now?

If you’re already running rubber because you can’t use steel on your contracts, polyurethane is a direct upgrade in every category that matters. It clears better—polyurethane stays rigid enough to scrape clean on the first pass instead of folding and dragging like rubber does in cold temperatures. It lasts dramatically longer—our customers typically report 3–5× the service life of standard rubber in comparable conditions, which means fewer mid-season blade changes and less downtime. And it still provides the surface protection your contracts require. The reversible design doubles the usable life even further.

Will polyurethane clear snow as effectively as steel?

Our polyurethane formulation maintains the rigidity needed for effective first-pass clearing on commercial surfaces—parking garages, concrete lots, asphalt, and sealed surfaces all get a clean scrape. It clears significantly better than rubber because it holds its shape in cold temperatures rather than deflecting under load. You lose the ability to scrape ice off a surface the way steel does, but for snow clearing on properties where steel isn’t allowed, polyurethane delivers the closest performance match without the surface damage.

How does polyurethane hold up over time in heavy commercial use?

In the high-wear environment of commercial snow removal—repeated passes, heavy down-pressure, abrasive surfaces—how an edge wears matters as much as how long it lasts. Polyurethane wears evenly and smoothly, maintaining consistent clearing performance and surface protection throughout the season. Our customers in commercial applications typically report 3–5× the service life of standard rubber edges. Install it, flip it when one side wears down, and trust that it’s performing just as well on your last lot of the night as it did on your first.

Can I use this in a parking garage?

This is one of the best applications for polyurethane. Parking garages present a unique combination of challenges that polyurethane handles better than any other edge material: the coated concrete floors are expensive to repair and easily scratched by steel, the enclosed structure amplifies steel-on-concrete noise to the point of being physically uncomfortable, and the constant expansion joints and garage thresholds catch rigid steel edges and jolt the equipment. Polyurethane clears the coated surface without scratching, operates at a fraction of the noise level of steel, and flexes over joints and transitions instead of catching on them.

What’s the difference between polyurethane and UHMW or HDPE plastic edges?

You may see cheaper “poly” edges sold online made from UHMW or HDPE plastic. While those materials offer some surface protection, they lack the rigidity and abrasion resistance of true polyurethane—a critical difference in commercial use where you’re putting serious down-pressure on the edge and running it across abrasive concrete for hours at a time. Our urethane formulation is specifically engineered for snow plowing—it stays firm enough to scrape effectively in temperatures down to –50°F while absorbing impacts that would chip or crack harder plastics. Polyurethane also has superior rebound memory, meaning it returns to its original shape after flexing over expansion joints and surface obstacles rather than permanently deforming under repeated stress the way UHMW can. For commercial operations where the edge has to perform under real load, the difference matters.

How difficult is installation?

Installation is straightforward. The edge is supplied as an undrilled blank—use your existing edge as a drilling template with standard power tools. At 84″ and 1.5″ thick, you’ll want the edge supported on a flat surface during drilling. The polyurethane material drills cleanly with standard bits at moderate speed. We include detailed mounting instructions with every purchase, and our knowledgeable staff is available if you have questions about your specific equipment.

Is the edge really that much quieter than steel?

The difference is dramatic—and in enclosed spaces like parking garages, it’s the difference between a functional working environment and an unbearable one. Steel-on-concrete in a parking structure echoes and amplifies to the point that it can cause hearing damage during extended shifts. Polyurethane operates at a fraction of that noise level. On open commercial lots and residential neighborhoods, the reduced noise means you can start earlier, run later, and serve noise-sensitive clients like hospitals and residential communities without generating complaints.

What if it doesn’t work for my setup?

Our products are backed by a Satisfaction Guarantee. If something isn’t right, we’ll work with you to make it right.